What Are Quarters Made Of?

The United States quarter is made from 91.67% copper and 8.33% nickel.

The quarter is the workhorse coin of the United States monetary system today. While the cent, nickel, and dime have increasingly become bit players in daily cash transactions, mainly helping round out correct change, the quarter continues its dominance as a major player in day-to-day life for so many Americans. From use in cash-only vending machines and at toll plazas to enabling shopping carts at discount grocers and even bringing game machines to life at vintage arcades, the quarter remains an important part of the nation’s economy.

Washington quarters have been in circulation since 1932, originally made from 90% silver.

And it’s funny we should talk about “bit players” in this look at the quarter, because this denomination has long been nicknamed “Two Bits.” As numismatic historians know, the “Two Bits” reference goes back to the days when the Spanish Milled Dollar was still in widespread use in America. The large silver coin, which inspired the creation of the United States dollar, was commonly broken into eight pieces. This gave rise to the common term “Pieces of Eight.”

An eighth of a Spanish dollar, or one bit, equals 12-1/2 cents. And two bits? Well, you can do the math on that… (Hint – two bits equal 25 cents!)

Making the Quarter: Quarter Coin Changes Through History

When the United States quarter debuted in 1796, it was originally struck with planchets that were 89.24% silver and 10.76% copper. This metallic composition continued until 1837, when the silver fineness was rounded out to 90% purity.

The quarter chugged along with its 90% silver, 10% copper composition until more than midway into the 20th century, when rising silver prices promoted changes. By 1963, the silver price had increased to the point that the intrinsic value of the silver within a quarter was worth more than the face value of the coin. This led many to hoard quarters and other silver coinage from circulation, contributing to a nationwide coin shortage.

The United States government handled the situation by removing all silver from the quarter (and dime) in 1965 under a coinage act signed by President Lyndon B. Johnson. Beginning in 1965, all circulating U.S. quarters were struck with a copper-nickel composition. This is the same metallic profile used for striking the denomination today.

Was that the End of Silver Quarters?

The copper-nickel clad revolution of 1965 didn’t spell the end of silver in the quarter – not by a longshot! In 1975 and 1976, the United States Mint began striking some 1776-1976 Bicentennial quarters commemorating the nation’s 200th birthday in a 40% silver clad composition. These coins were issued expressly for collectors and included in some uncirculated and proof sets.

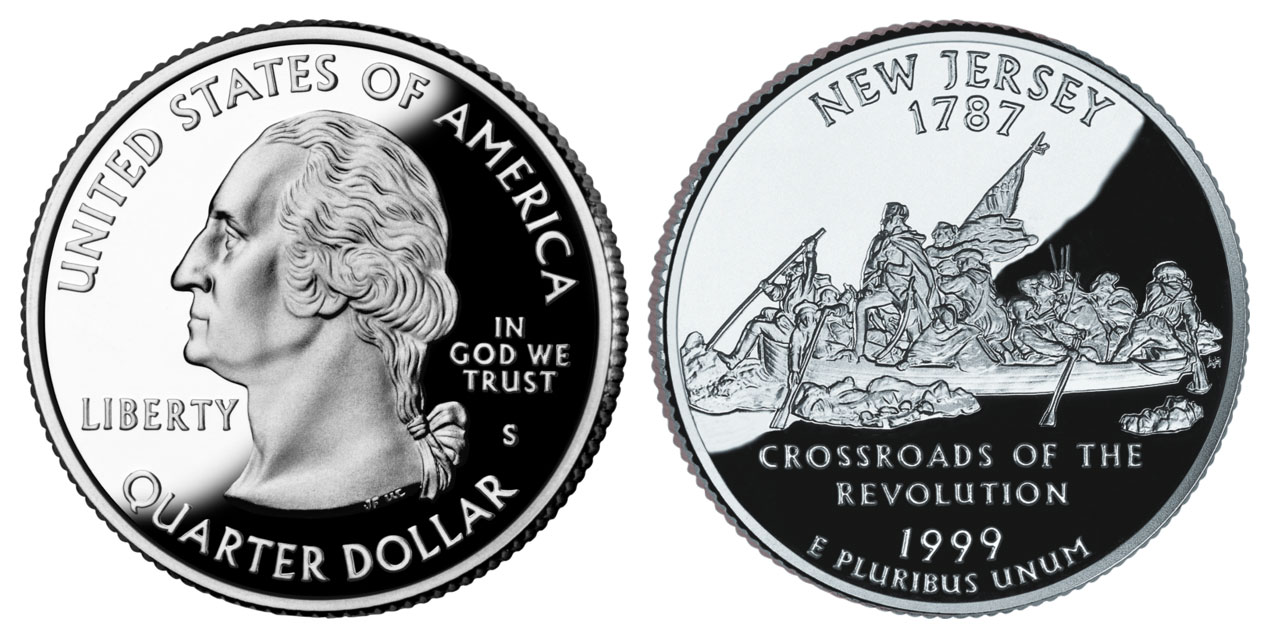

Sixteen years later, the United States Mint struck its first 90% silver quarter with the first of the modern-day silver proof sets, which debuted in 1992. These 90% silver proof quarters became highly popular with collectors, with millions struck each year during the height of the height of 50 State Quarters program beginning in 1999 and lasting through 2008. Subsequent commemorative quarter programs also saw large emissions of silver proof quarters for collectors.

1999 New Jersey proof quarters were only made for one year, and include a 90% silver version.

The U.S. Mint still strikes silver quarters for proof sets and many other numismatic offerings. But since 2019 the silver purity of these coins has been increased to .999 fine.

Also of note are the five-ounce silver America the Beautiful quarters, which carry a nominal face value of 25 cents. These massive silver quarters were marketed primarily as bullion coins but are considered “quarters” for all intents and purposes by some collectors.

How Are Quarters Made?

The circulating quarter is struck in a fashion similar to how other coins are made day to day at the United States Mint. The first step in making a quarter begins by cutting little quarter-sized discs from a long metal sheet that produces thousands of blanks. These blanks are then annealed, subjecting them to heat reaching temperatures as high as 1,600 degrees Fahrenheit.

After annealing, quarter blanks are then washed and dried to help them appear shiny and remove any debris and other foreign matter on the surface. Then, the blanks are moved onto the upsetting mill, where a slight lip is imparted around the perimeter of the disc to prime the area for its eventual rim. Once blanks have been upset, they officially become known as planchets, which are pieces of metal prepared for being turned into coins.

The quarter planchets are then fed into the coining presses, where dies strike designs onto the obverse and reverse, while the retaining collar keeps the planchet properly centered upon strike while simultaneously imparting the coin’s reeded edge. After the newly minted quarters are ejected from the striking press, they are inspected to ensure that they were properly struck and are free of errors.

If you want to know more about how coins are made, follow the link to learn more.

After passing inspection, the quarters are counted and bagged. Then they are shipped off to the Federal Reserve, after which they are distributed to banks, credit unions, and other financial institutions around the country – filtering into widespread circulation and, eventually, finding their way to you!

Joshua McMorrow-Hernandez is a journalist, editor, and blogger who has won multiple awards from the Numismatic Literary Guild. He has also authored numerous books, including works profiling the history of the United States Mint and United States coinage.

Read more about United States coins from numismatic experts:

More from the Gainesville Coins Blog about coin collecting:

Collector Resources for Understanding the Hobby of Collecting Coins

What Is a Proof Coin? Overview for Coin Collectors

What Is an Uncirculated Coin? Guide to Condition and Value

What Is a Brilliant Uncirculated Coin? Beginner's Guide

What Is a Gem Coin? Understanding Quality, Rarity, and Value